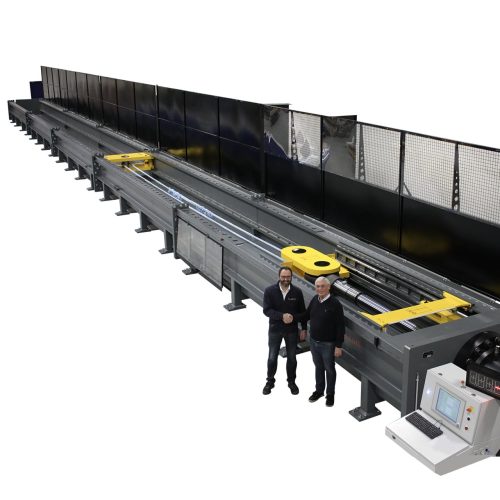

Cutting industrial wire ropes

The video demonstrates working with our Type 1224 annealing machine. It illustrates the fundamental principle of separating a wire rope with a cutting and annealing machine. Depending on the wire rope diameter and the desired tapered end length the clearance between the clamping jaws is set before clamping the wire rope. Press the foot pedal to start the current flow, and the rope starts to glow. The wire rope is now slowly turned according to its lay direction and simultaneously pulled apart. The result is a professional looking tapered end on both sides of the rope. The fundamental work process applies to our entire annealing machine programme Type 1224-1226.