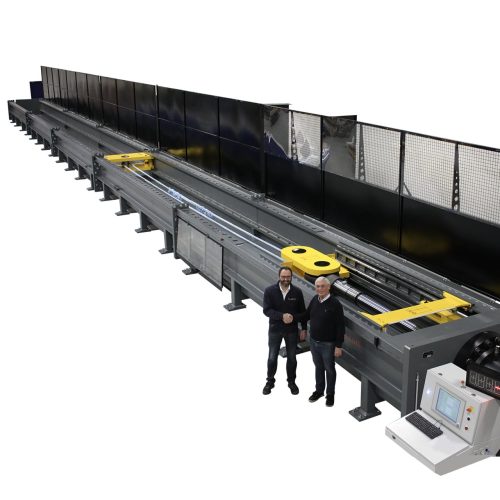

Our hydraulic swaging press in use

This video demonstrates working with our 4,000t swager. It illustrates the fundamental principle of swaging an aluminium ferrule. This includes an example of a wire rope sling with a thimble. This fundamental finishing process applies to our entire swager programme. The rigging arm shown is very helpful for all wire ropes with diameters above 38mm. It saves time, is safe and ergonomic. The rigging arm is available for all our swaging machines above 1,000t