Swaging a wire rope sling

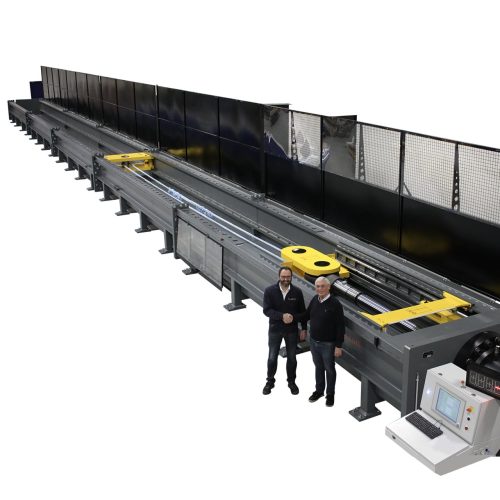

This video demonstrates working with our 6000 kN swager. It illustrates the fundamental principle of swaging an aluminium ferrule. This includes one example of a simple wire rope sling and one example with a thimble. This fundamental finishing process applies to our entire swager programme. The integrated automatic function is very helpful if you have to process large batches: without taking your foot off the foot pedal, the press closes and opens again as soon as the set pressure has been reached. You can preset the return stroke in the process. This saves time and is ergonomic. The controls have similar design on our 415 kN PLUS, 900 kN, 1500 kN PLUS, 3000 kN, 12500 kN, 20000 kN and 40000 kN machines.